OPTI 599 optimizing crosscut saw

High-productivity plant with MERLIN Q scanner and two OPTI 599 crosscut saws

OPTI 599

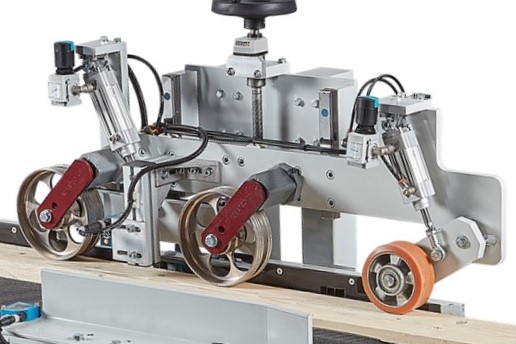

The OPTI 599 is a high-performance crosscut saw which can increase your productivity by up to 30% compared to traditional ones. Designed for use in high-production lines for heavy-duty non-stop operation, it employs a hardened steel helical toothed roller drive system incorporating a powerful brushless motor that guarantees a 260 mt./1’ feed speed.

Cutting takes place by means of a connecting rod movement controlled by a brushless motor with 0.15 second cutting times.

The rejects are ejected at the rear at the moment of cutting and the sizes are separated at the exit on the sorting belt by means of lateral ejectors.

OPTI 599 with reading station

The board dimensions and the defects marked with fluorescent chalk are detected by a separate reading station or automatically by an MERLIN Q scanner. The high-speed scanner controls every side of the board and reads its characteristics and defects in an accurate manner that no operator could ensure. The data processed are sent directly to the saw at high speed in order to execute the cut.

Loading and unloading can be fed automatically by means of:

CT4 layer loader with vacuum system and recovery of the strips.

SC1, single-size stacker with angular elements.

SC4, stacker with mobile angular elements for simultaneously unloading different sizes.

| TECHNICAL DATA | OPTI 599 | |

| Blade diameter | mm. | 450/550 |

| Motor power | kw. | 5,5/7,5 |

| Feed speed | mt./1′ | 260 |

| Cutting capacity | mm. | 45×200 (ø450) 80×240 (ø550) |

Gallery

Video

Automatic plant with OPTI SCAN 4 scanner and two OPTI 599 crosscut saws

OPTI 599 crosscut saw with OPTI SCAN 4 scanner

Crosscut saw mod. OPTI 599. Marking of defects by chalk up to 8 different qualities.

Cutting test, production capacity